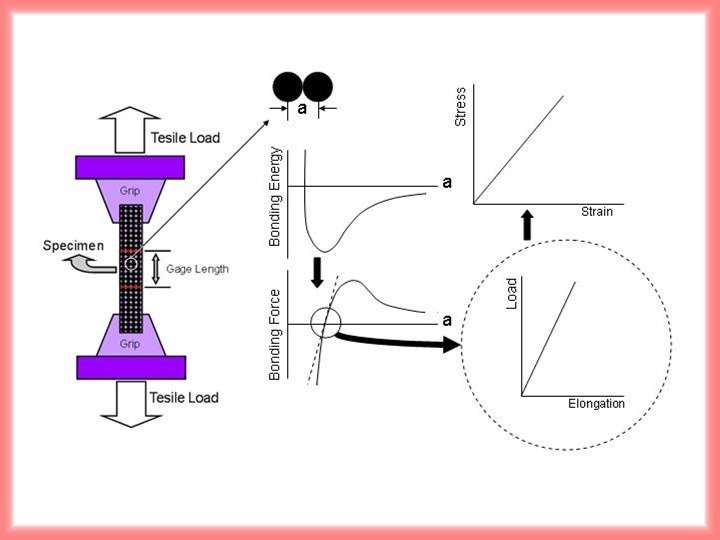

Tensile Test

The tensile test may be the most widely used test to determine the mechanical properties of structural materials. The key feature chosen to be a favorate test in the material science field is probably the high productivity of a large amount of information even from single test. The specimen material is pulled by tensile load at a constant rate until it fractures. During the test, the tensile load and the elongation of the gage length of the specimen are monitored and recorded. From those data, stress and strain are obtained through simple calculations as well as other mechanical properties such as yield strength, tensile strength, the modulus of elasticity, and qualitative thoughness of the material. Understanding fundamental mechanism of the deformation can be easily achieved in the view of the atomic scale. The mechanism of the elastic deformation is the streching of atomic bonds. On the other hand, the mechanism of the plastic deformation is the distortion and reformation of atomic bonds.

Schematic feature of the device and Atomic-Scale Relationship

The area of the gage length is the place where any significant deformation at higher stress is localized at. The size of the specimen depends on the size of the device - detectable elongation from nanometer to macro scale.